What is a Wiring Harness?

What is a Wiring Harness?

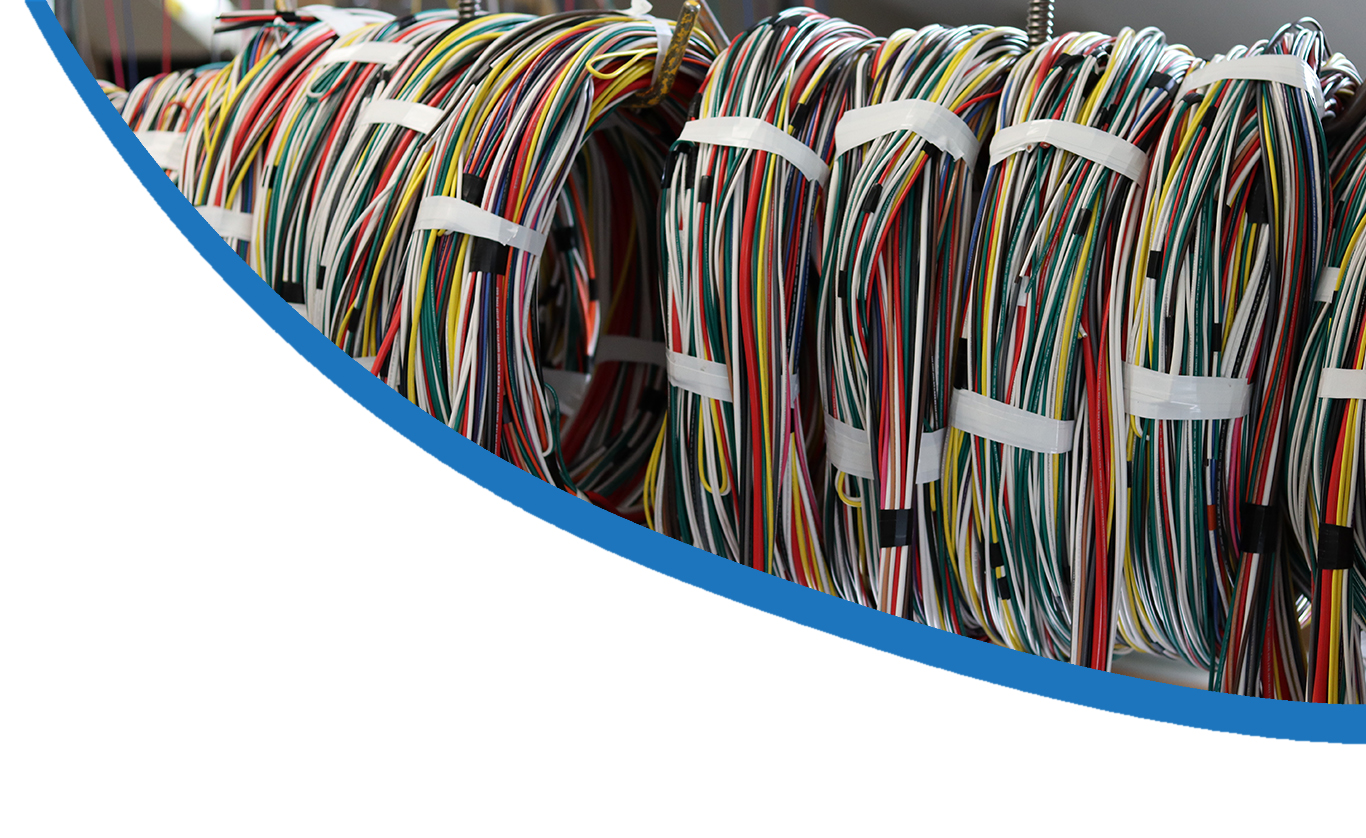

A wiring harness or also known as a cable harness, wire harness, cable assembly, wiring assembly, or wiring loom, is a group of electrical wires that have a protective outside coating that is bundled together to form a harness. The purpose of a wire harness is to transmit an electrical signal or power to a device. The bundle of wires is bound together and held in place by cable tie, tape, or any other binding material. It is then installed and fitted into the electrical component they were designed for. Then it will be fitted with a type of connector, pin, or terminator specific to its function. A connector, terminator and wire are the three basic components of a harness.

Wire harness sizes can range anywhere from a few small wires installed in computers to thousands of wires bundled together to give power to an aircraft. Not only can the number of wires vary but so does the weight and price of the harness.

Many people are unaware that wiring harnesses are used very commonly and can be found in almost all electric items around you. Some of the devices that people don’t realize wire harnesses are installed in are cars, machines, recreational vehicles (RV), airplanes, medical equipment and much more!

What are the benefits?

Choosing to manufacture a wire harness for your electrical device over loose wires or cables can provide you and your business with several benefits.

Firstly, building a wiring harness can save you a lot of time installing, making the job much easier. It is more efficient to build the harness on a table then to individually install and route each wire into the device. In addition to individually installing each wire you will then have to connect each wire to a terminator or connector. It is much faster to install the bundle of wires all at once, with the necessary connectors already attached.

Secondly, installing a wire in your electrical device helps to maintain organization and optimize the usage of space. For example, some bundles of wire are hundreds of feet long when fully extended. At full extension it would not fit compactedly inside a RV or aircraft. Moreover, bundling the wires in a harness prevents loose wires hanging out or taking up space.

Lastly, a wiring harness helps to minimize damage to the wiring or cable. By bundling the wires or cables into a harness better protects them against the adverse effects of abrasions, vibrations and moisture. It can also decrease the risk of a short occurring.

How can Mega Directline Inc assist you in building a wiring harness?

Mega DirectLine Inc has been building high-quality wiring harnesses for over 20 years. With experience in manufacturing for the RV, automotive, and specialty shop industries, we have built harnesses varying in different sizes and functions. Mega DirectLine Inc works with its clients to build a wire harness to their exact specifications, using blueprints and schematics. Using up-to-date machinery and the best technicians, your harness will be built with precision!

Wiring Harnesses In Your Industry

The Manufacturer’s Edge

- Less Time on Your Dime

Less time = less money spent on production which is the winning combination we are all striving for

Purchasing /Inventory – No need for detailed wire tracking, ordering, or carrying of costly wire inventory. Simply tell us which units you are running and how many and we take care of the low voltage wiring harnesses!

Assemblers –With Mega DirectLine you can reduce staff from your production line. We provide ease of installation in the form of a bundled drop-in wiring harness which simplifies the installation process. Installers have all the wiring they need at the required locations making the wiring process more efficient, saving you both time and money. - Consistency

Mega DirectLine’s wiring harness building system ensures every harness in an entire run is built exactly the same. There are no surprises mid run. - Customized Harness

Every harness is built to the specifications you provide. Harness changes are made as soon as we are notified. - Customer Service

We believe that customer service is a priority, if you are faced with an issue we stop and drop to aid you until your issue is resolved. - Quality

We are IPC certified trainers and we train our staff to these standards. We use only UL and CSA approved wire, pins, connectors, and parts in our harnesses.

The Consumer Advantage

- Quality

We are IPC certified trainers and we train our staff to these standards. We use only UL and CSA approved wire, pins, connectors, and parts in our harnesses. - Low Voltage Option Ready

The harnesses leave our facility low voltage option ready; this allows for easier updates down the road. - Consistency

Mega DirectLine’s harnesses are designed and installed in designated channels throughout the unit meaning finding junctions and locations is simple. - Confidence in Product

Our low voltage harnesses are designed with independent power and grounds to each location, there by simplifying the process of locating circuits making troubleshooting or updating fast and easy. - Safety and Security

Mega DirectLine harnesses are securely bundled. Running wires in bundles protects them against possible vibrations, abrasions and moisture. Wires bundled together also reduce the risk of electrical shorts,